Waste / Residues to Products

Waste / Residues to Energy

EBRI can help you:

- Produce new high value materials from your organisation’s organic waste and residues which can be commercialised.

- Develop new opportunities in growing, low carbon marketplaces, such as ‘biochar’.

- Explore new ways to meet your company’s environmental, social and governance goals.

- Adopt new technologies to help you become more resource and energy efficient.

- Decarbonise your business model.

Text

Text

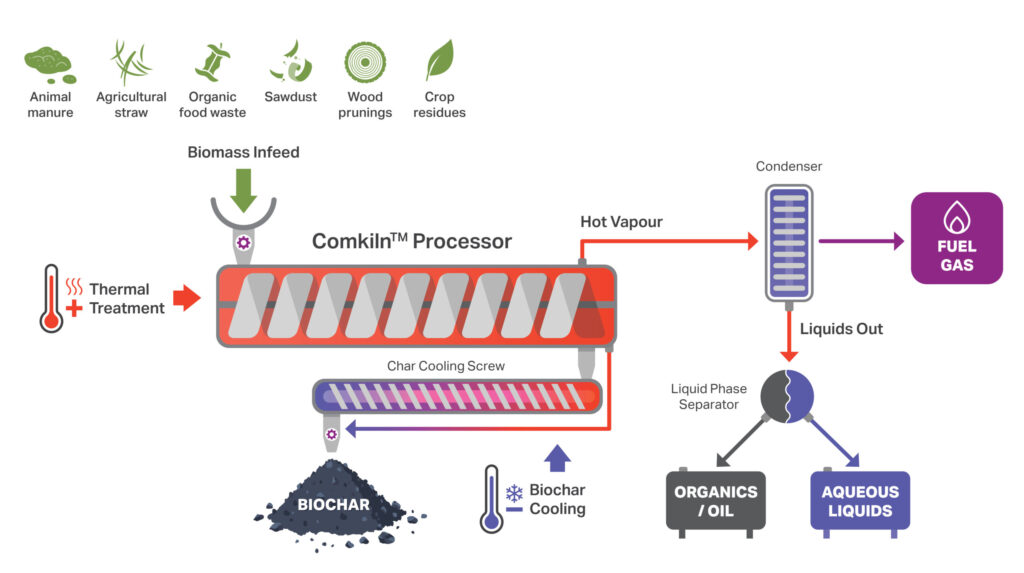

The Energy & Bioproducts Research Institute (EBRI) at Aston University and our industrial partners have developed a range of innovative technology able to transform organic material such as sawdust, fallen and diseased trees, dried chicken manure and agricultural straw, into commercially valuable bioproducts:

- Biochar

- Gas

- Heat

- Liquids

Text

Text

EBRI can help you develop new opportunities in the growing ‘waste / residues to energy’ and ‘waste / residues to products’ marketplaces, such as these:

Text

Bespoke support from EBRI

- ‘Waste / Residues to Energy’ Insights

Discover how organic waste and residues can be thermally treated via a process known as pyrolysis to generate commercially valuable gases, heat and liquids. - ‘Waste / Residues to Product’ Insights

We can help you explore low carbon products that can be generated from the pyrolysis process with the aid of our technology. - Consultancy which could include:

- Lifecycle Assessment (LCA) – to estimate the energy and climate change impacts and the economics of – pyrolysis technology systems.

- Pyrolysis technology and use case consultations.

- Bespoke feedstock and biochar testing.

- New product appraisals.

- Demonstration events

EBRI Technology

We are offering exclusive consultations to organisations who are interested in adopting and deploying our pyrolysis technology known as Comkiln™.

Production Process: Direct to Condenser

Derived products: Biochar, aqueous phase liquids, organics and non-condensable gas

So what

ex

Production Process: Direct to Vapour

Derived products: Biochar and Heat

Text

Text

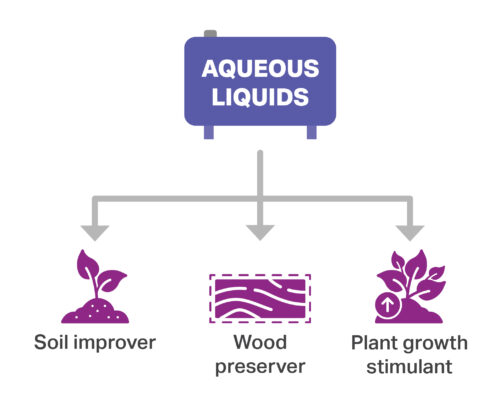

Derived Products and Applications

Biochar

Vapour

Liquids

Organics

Fuel Gas

Download brochures

Commercial and Environmental Carbon Reduction Technology

Carbon Reduction Technology for Business

Get in touch

We are particularly interested in hearing from organisations that produce large amounts of organic waste and residues for instance in the agriculture, timber or forestry sector, or from companies requiring industrial heat for example to transform material into useful products. Similarly if you are a large producer of composites, ceramics or 3D printed products we would love to talk to you.